Race, Crash, Fix, hopefully not repeat but sometimes you do...

Repairing a factory-built BMW M4 GT4 race car after a wreck at VIR

When I tell people that I prep BMW race cars and travel the country for endurance racing, the conversation always turns into stories of crashes, victories, comebacks, blown engines and late nights making repairs. Fortunately, in over 7 years of prepping cars for numerous club endurance and sprint racing series’, we haven’t had any drivers take a trip in the boo-boo bus but we have had some wrecks that could’ve ended a lot worse. If the only injuries in a weekend were acquired while shaking the shekel tree then that is okay; difficult to accept sometimes, but better than a hospital trip.

In July we were racing at Virginia International Raceway (VIR) and it was a brutally hot weekend. The front straight runs West to East, so if you are standing in the pit lane facing the track then you have your back facing South towards the sun all day. I don’t spend much time in the South during summer months, I’m a Masshole and our “hot season” is basically just from late June into August and occasionally we have a year that varies from the norm. Maybe it’s no big deal for it to be 87°F at night, 95°F during the day, with 100% humidity and no wind but to me it was an absolute sack-sticker. I could tell that locals around me weren’t having it either. When it is that miserably hot out and with minimal relief, it throws a lot of people off from any normal routine they’ve gotten used to. If you’re working all day doing pit stops and up late at night working on the car, you better hope you have a comfy, air-conditioned sleeping space to crash that night so you can get a decent rest for the morning. If you’re a driver, you really want to make sure you are physically and mentally ready to hop in a scorching hot car for a few hours. Drivers experience a quicker onset of fatigue, heat exhaustion, dehydration and are more likely to make mistakes; even if the interior of the car has air conditioning like with our BMW M4 GT4. The air-conditioning system in the GT4 is really only designed to reduce the interior temperature of the car from uninhabitable to borderline unbearable when it is in the 90’s with high humidity.

Two hours into Saturday’s 9-hour race, our driver got spun off track by another car at a section called Roller Coaster which is appropriately named due to how it dips and rises in elevation while alternating directions as it ultimately sends you downhill onto the front straight of the track. If you lose control of the car at a high speed here, the off-camber nature of the short grass runoff space makes it physically difficult to regain control and slow the vehicle to keep it away from the guard rail.

After examining the data retrieved from the car’s onboard computers at a later point, I determined that it was spun at around 85-90mph and slowed to about 45-50mph before making impact with the guardrail with the drivers front corner of the car. As soon as our driver was on the radio with me telling me he got spun off and crashed, my phone was buzzing with texts from concerned friends and family watching our live video stream online from home. They already knew more than I did. A lot of things happen all at the same time, other crew members were rewinding the footage of the wreck so they could play it back for me to try to gauge the severity while I was asking our driver if he was okay. After getting a relieving response from the driver about his condition, I then asked if the car was stuck or seemed “wadded up” or “lightly crunched” and his response was “unable to determine”. I told him to shut the engine off due to a quickly apparent concern of possible engine damage or a fire erupting due to coolant and engine oil that was already escaping. I later conducted tests and evaluated data logs from the vehicle to determine that no engine damage occurred as a result and aftermath of the impact.

After the car was towed back and off-loaded from the tow truck, it was pretty apparent that the damage wouldn’t be repairable at the track and the car wouldn’t be able to continue racing the remainder of the weekend. My attention was momentarily shifted to thinking about how bad I felt for the emergency workers who had to do the often-thankless job of towing our car outside in the 95°F heat while bundled up in heavy fire retardant gear. You gain a greater appreciation for the emergency workers when you realize that they’re wearing 3” thick clothing that looks appropriate for a sub-zero snowmobile expedition across the Alaskan tundra except it’s hotter than the devil’s dick outside and they’re out there crawling underneath crunched up race cars to hook them up onto the truck. I thought that zipping up my fire suit to briefly execute a pit stop a few times throughout the course of the day was hot, those workers wear that shit all day long.

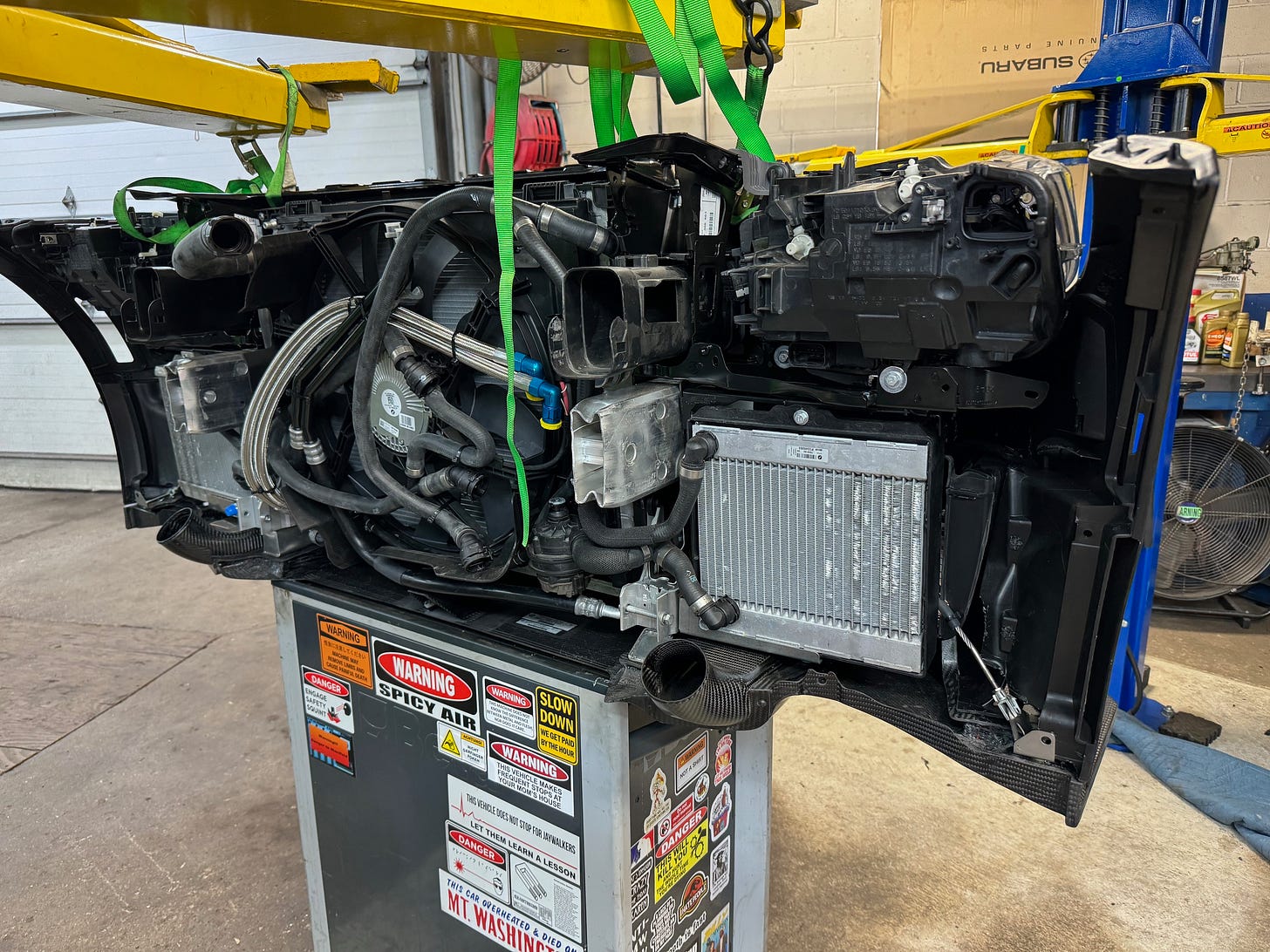

The entire nose of our car was ‘smashed to bits’ as we say. The drivers side frame horn was buckled outward, the radiator support structures, radiators (there are a lot of them), oil coolers, front subframe, upper apron support, suspension control links, frame deformation elements (sacrificial extended aluminum frame sections), brake cooling ducts, carbon fiber splitter, headlights, bumper bar, transmission oil cooler pipes, splitter bowden cables, strut tower ‘boomerang’ brace, and just about everything else in the nose section or ‘clip’ was crunched, bent, twisted or broken. Totally fuckin’ fucked mate, big-time! Even if we had a full spare nose clip ready to go, the bent frame section wouldn’t be something I’d properly fix at the track on this particular car. So, I flew home early after consulting and placing orders for parts with our BMW Motorsport Parts Rep who was there for the event…

…But before going home, we were also sure to get some delicious Carolina BBQ. The Checkered Pig is technically in Danville VA right on the border with North Carolina, so pardon my political incorrectness BUT they had a proper Carolina-Style BBQ menu and did not disappoint. The fact that they have 5 different flavors of their Carolina vinegar sauce in bottles on each table made me know it was going to blow my tits clean off. Loaded pulled pork and brisket nachos were pretty fire, and trying all of their sauces was satisfying. We also made jokes about the fact that Danville Virginia is right next to Martinsville Virginia…Yeah I’m kind of a big deal around here.

The ridiculous smorgasbord of BBQ put Carl into a food coma, he was laying in the back seat of my rental truck like a woman going into labor on the way to the hospital.

Back home, I immediately went to work when the vehicle was in my possession on my lift. I dismantled all of the sad broken things from the car and made various lists to get the ball rolling on fixing it ASAP. The M4 GT4 shares many core parts with the street-going BMW M4 production car but it also has a lot that has to be special ordered through a BMW Motorsport authorized dealer and is only used on their factory-built race car. This is not any BMW Dealer, and any random person can’t call or walk in and place orders for Motorsport parts and install them on their street car; and for very good reasons. They’ll want to make sure that you actually have the car you claim you do to allow you to buy parts and you need to be able to verify some identity and vehicle ownership to get a login to their online information system. BMW’s corporate policies regarding parts and spares ordering makes them very helpful and cooperative with Customer Racing teams. I consider the M4 GT4 to be a true Gentleman’s Race Car because BMW is extremely accommodating in making the parts ordering process as easy as possible and our particular Motorsport parts rep even began sourcing parts that other race teams were selling when there were things that couldn’t be delivered to meet our time deadlines. Industry people who do things in the best interest of others and not just themselves get a good rap, I appreciate that he was dedicated to solving any issues with getting things that were backordered by reaching out to alternate sources. I ultimately began putting together parts lists which I organized based on whether they could only be ordered from our Motorsport Dealer hundreds of miles away or if they could be purchased from our local BMW Dealer. This basically involved separating the race parts that aren’t used on street cars from the regular production parts….and there are a lot of them. Over 1,000 line items, to give someone a ballpark number.

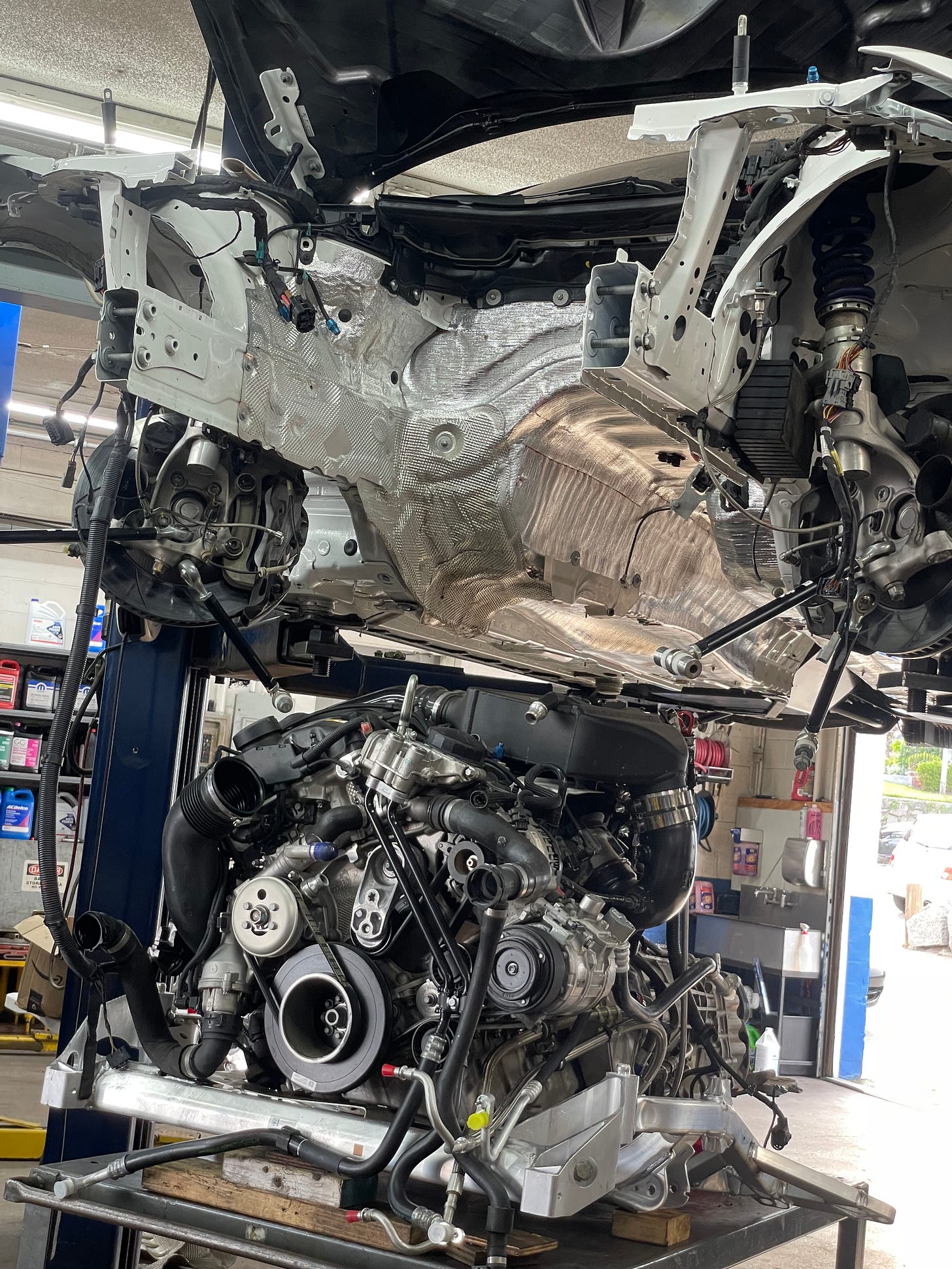

Rewind to while I was at the track: I had removed the broken suspension links and tossed in a set of spares just so that the car could be winched into the trailer without fighting us more than it already was. The left front wheel was flopping and was stuffed up into the wheelhouse because the lower control arms were broken in half and no longer keeping them aligned. I knew that the front subframe was buckled so it was one of the first things that we ordered and one of the first things to arrive seeing as it is a common component with the production car. At home, I dropped the engine out onto a heavy-duty movable table with the transmission, front subframe and accessories and installed the new replacement subframe so that the car could be rolled into a trailer so the chassis could be repaired by a collision shop that we use. The damaged chassis sections were also shared with the street-going model so they arrived early and weren’t special order items on a slow-boat from Germany. The collision shop gave us a 3 week ETA which was spot-on accurate, and I spent that time sorting through parts deliveries as they came in and began prepping parts for installation.

In the next 2 photos, you can see how the end of the drivers frame horn or ‘engine support section’ is bent outwards. This is the damage that wouldn’t be reasonably repairable at the track.

Many of the parts that are shared with the regular production car get installed exactly how they are as you remove them from the packaging, but there are also so many that require trimming and modification in order to be usable for their race duties. The front bumper cover on the GT4 does not fit exactly the same way that it does on the street car and there are alterations that need to be made to radiator ducts, plastic shrouds, auxiliary radiator brackets, the front deformation elements and many other parts in the front end. If someone expects to just slap a nose together in a couple of hours, they should know that the parts to assemble a nose take up the space of a small box truck and require a lot of tools to perform the trim work to make them fit. You aren’t doing this with one of those $99 briefcase toolsets they sell near the checkout at Autozone. The mound of cardboard that is created after flattening all of the boxes that the nose parts came in is significant. You could have a breakdancing competition for days in the shop with the amount of cardboard we had.

The collision shop that repaired the chassis damage is considered to be the best in the business, race teams running BMW and Porsche GT cars from all over the country ship their damaged cars to them to have chassis repairs made. The repairs are done so well that one cannot tell that it was ever in a wreck no matter how closely they inspect the affected area. BMW has repair guidelines for various types of chassis damage, and they explicitly outline what their approved repair method is for each chassis section so that the vehicle is still structurally sound and will perform as intended in a collision again in the future. I have a huge amount of respect for people who adhere to those guidelines, do their repair work by the date promised, and do it to such a high quality that even the most observant person can’t tell it was once damaged.

Putting the car back together was very straightforward, I work on enough BMW’s old and new that the process of removing an engine, transmission and subframe onto a table has become routine and subconscious. You sometimes forget that you’re working on a race car to be honest, because the engine and running gear is so similar to what is in the street-going car; but you still have to follow many different assembly steps that BMW has created for the GT4 that you wouldn’t ordinarily do to any M4. There are some major parts variations that aren’t even remotely similar to what is in the production car, so I wouldn’t ever advise someone to attempt to make repairs to the GT4 without the proper technical data and literature from BMW Motorsport. I won’t get into depth on that in my blog because I’m sure BMW doesn’t want specific details of their engineering to become public knowledge. I will say that you couldn’t ask for better documentation and support for a factory-built race car than what BMW has provided for the M4 GT4. The technical manuals answer any question you could have about the technology in the car that you otherwise wouldn’t know by repairing their street cars for a living every day. If you work on race cars and are familiar with Motorsport electronics, then they have made everything easier than you could ever ask it to be in that regard as well. It is a very technician-friendly car with incredible forethought and sensibility in its engineering.

We don’t consider ourselves to be overly superstitious, but we do believe in fate, Murphy’s Law, karma and the writing sometimes being on the wall. Learning from something helps us to be better prepared in the event that it happens again, and failing to prepare ourselves for if it will just encourage it to happen that much more. It’s karma, fate and all those things that are eager to kick you in the balls any chance they get, so you have to take extra precautions against them. We talk about epiphanies and things that keep lingering in our minds, voices in our heads telling us that if we don’t do X then Y or Z will happen but if we cover our asses then it’ll keep us out of trouble. We didn’t want to be switching flights and heading back home early over something similar happening again, so we came up with a plan that we had seen race teams in Pro series doing.

The easiest thing that we thought of was to build an entire spare nose seeing as I was already building one for the car anyway and the entire front end was apart. Basically just order doubles of everything we were already ordering for the nose. A lot of race teams with a big budget and a larger transporter will bring multiple cars so that they have another one to drive in the event that one gets hurt bad. It also makes it easy so that your crew members wouldn’t have to stay up straight through the night repairing major accident damage and teams can use one of the other cars to get their drivers more practice time during testing. Our solution of building a spare nose clip was the best thing we could think of that didn’t involve buying another car and a larger trailer and transporter. I actually built the spare nose on the car first, and made sure that the fitment was satisfactory and then I removed it as one big sub-assembly and installed the final one that was staying on the car. The spare nose was assembled with everything you would typically crunch up if you smacked the front end into something. Every hose, clip, bracket, radiator, duct, pipe, the entire bumper cover, spare headlights and everything ready to go; and then it was packaged up and stored in the race trailer along with a spare subframe. It’s good to even zip-tie a bag with the assembly hardware to the nose clip somewhere so you aren’t looking for it in a pinch. The only time you would ever be looking for those bolts would be if you were replacing the nose clip, so it doesn’t make sense to put them anywhere other than with the nose clip. If you’re going up into the rafters of the trailer to get a gigantic 5 foot wide nose clip of a car that weighs 150lbs., you’ll probably be looking for a few other things at the same time.

It’s a lot easier to attach all new hoses to the spare nose during assembly than to keep them in boxes somewhere; this way you don’t have to search for them, they are already connected, and you know where they go. The hoses and pipes typically get destroyed/damaged in a front-end wreck anyway, so it only makes sense to just have them already installed on the new nose clip.

You’re better to have it and not need it than to need it and not have it. The only thing better than having it with you in boxes everywhere is having it pre-assembled and organized so that when the day comes that something similar happens and everyone gets Deja Vu, it can be repaired quickly. A similar front end hit but without frame damage could be repaired in a couple hours or less, whereas assembling everything à la carte could take a few people all night depending on your organization and preparedness going to a race. Like a spare race engine, it’s one of those things that I look at when I walk in the trailer and cross my fingers it won’t be needed during the weekend but if it is I’ll be glad it’s there. The cost of flights and logistics just to have to return home 2 hours into Saturdays race makes the cost of building a spare nose clip worthwhile. The full cost of one of these front clips if you include the carbon fiber splitter, a subframe and a new carbon hood is about the same as the price of a well-optioned new Jeep.

We made our time deadline of mid-October for getting the vehicle repaired as well as completing some other improvements and modifications that aren’t super obvious. I was very thorough in double and triple checking things and not allowing anything that was even remotely in question to be allowed to hit the track. I don’t skimp on tool purchases, I follow repair instructions to the word, I keep a running log of component replacements so that we can replace them as they are coming up on time-out, and I don’t pretend to know answers to questions that I don’t know. Our next race with the car at Sebring FL the weekend of November 10th went well. The GT4 didn’t have a single mechanical issue and we spent our time during testing and qualifying to get the setup dialed in to find the best balance between tire life and handling performance. Time that you spend fixing things eats into time spent on optimizing and improving the car, and it eats into the practice time for your drivers. Both Saturday and Sunday we finished 5th overall out of over 60 cars, which I feel is acceptable but we’re always pushing to get a podium finish.

The F82 M4 GT4 is still a competitive GT4 platform but there are other more modern GT4 cars from BMW and Toyota (BMW) that we were competing against in the same class which are easier to drive at the same pace and are capable of even faster lap times at the same Balance of Performance (BoP). Our previous endurance car that we ran in numerous series is an E46 with 3.2L S54B32 that we built from a street car in 2018. We decided to retire it from endurance racing as it was proving to be very difficult to keep it performing on the same level against modern factory-built GT cars in the top class of Pro/Am endurance races. The E46 is still a very fast and capable car for racing, it’s just becoming increasingly difficult to campaign it the way that we were, and some components aren’t as easily sourced as they were in recent years. Drivers love the brute naturally aspirated power and responsive analog feeling of a mid-2000’s BMW but they also love having the nannies and creature comforts of the more modern car. The E46 still gets usage racing in the STU class of SCCA.